Why Indian Founders Are Doubling Down on ‘Credible Manufacturing’ in 2026

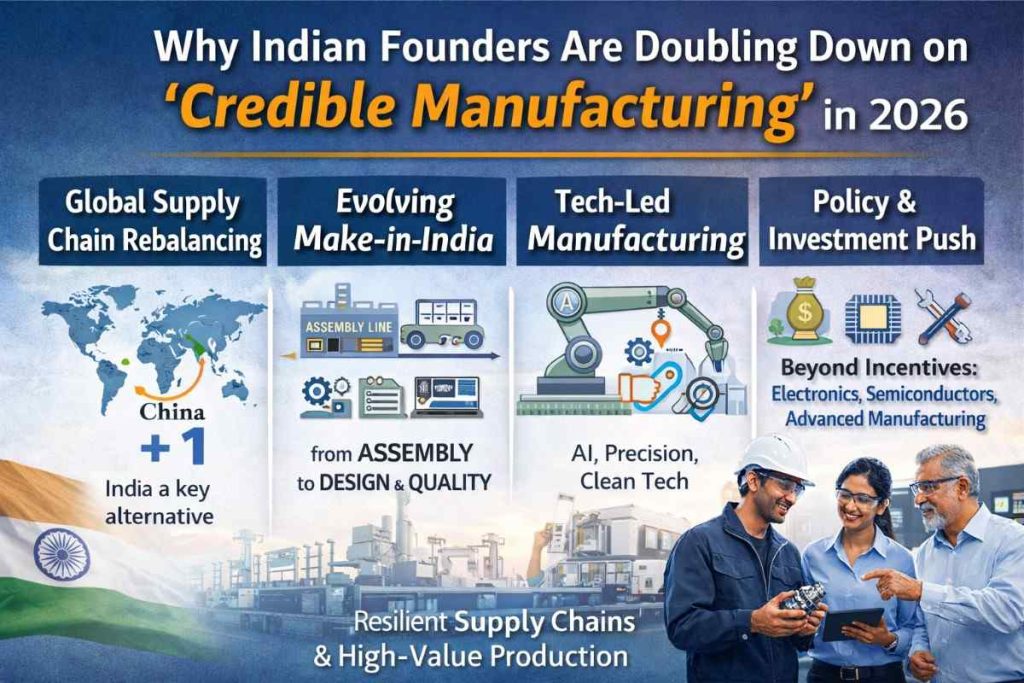

Indian founders are increasingly investing in high-quality, end-to-end manufacturing capabilities as the country moves up the global value chain in 2026.

In 2026, a quiet but consequential shift is underway in India’s startup and entrepreneurial ecosystem. After more than a decade dominated by software, consumer internet and platform-led businesses, Indian founders are increasingly returning to the factory floor. But this is not a nostalgic revival of old-style industrialisation. What they are building instead is something far more deliberate and strategic incredible manufacturing.

Across sectors ranging from electronics and electric mobility to aerospace, clean energy, precision engineering and industrial hardware, founders are investing heavily in end-to-end manufacturing capabilities that can stand global scrutiny. The emphasis is no longer on low-cost assembly or contract work alone, but on reliability, quality, intellectual property and engineering depth. For many founders, credible manufacturing has become both a competitive moat and a long-term bet on India’s role in the global economy.

This shift is being shaped by global, domestic and entrepreneurial realities converging at the same moment.

For years, India’s manufacturing ambitions were constrained by its position in global supply chains. The country excelled at scale and cost efficiency but struggled to move decisively into higher-value manufacturing. Much of the growth in electronics and consumer goods, for example, revolved around final assembly, with core components and design still sourced from overseas. That model delivered jobs and export numbers, but it did not build deep industrial capability.

By 2026, founders have become acutely aware of these limitations. Many who previously relied on imports or overseas suppliers faced severe disruptions during the pandemic years and the subsequent geopolitical tensions that reshaped trade flows. Delays, quality issues and sudden supply shortages exposed the risks of shallow manufacturing integration. As a result, founders began rethinking what it truly means to build a resilient business.

Credible manufacturing, in this context, refers to the ability to design, engineer and produce products locally with predictable quality, traceable supply chains and globally acceptable standards. It is manufacturing that customers, regulators and international partners can trust without hesitation. For founders, credibility now matters as much as cost.

Global dynamics have accelerated this rethink. As multinational companies diversify supply chains to reduce overdependence on a single geography, India has emerged as a preferred alternative. But the expectations have also risen. Global buyers no longer want just capacity; they want consistency, engineering collaboration and compliance with strict quality benchmarks. Indian founders who can offer these attributes are finding themselves in a stronger negotiating position, not merely as suppliers but as partners.

This has encouraged startups to invest in in-house capabilities that earlier generations avoided due to high capital costs and long gestation periods. In 2026, it is increasingly common to see young manufacturing companies owning critical parts of their production process, from tooling and testing to materials science and automation. While this requires patience and capital, founders see it as essential for long-term defensibility.

Technology is playing a central role in making this shift viable. Advanced manufacturing tools, data-driven quality control systems and automation platforms are helping startups achieve consistency that was once the exclusive domain of large conglomerates. Artificial intelligence is being deployed to predict equipment failures, optimise production schedules and reduce defects. Industrial internet-of-things systems allow founders to monitor output and quality in real time, even across multiple facilities. These tools are enabling smaller companies to punch above their weight.

Equally important is the growing focus on sustainability and compliance. Global customers increasingly demand transparency in sourcing, energy usage and waste management. Founders recognise that credible manufacturing in 2026 must also be responsible manufacturing. Many new factories are being designed with renewable energy integration, efficient water usage and waste reduction built in from the start. This is not only about environmental responsibility but also about meeting the procurement standards of international clients.

Policy signals have further strengthened founder confidence. While earlier manufacturing initiatives were often incentive-driven, recent reforms have focused more on reducing friction. Simplified compliance, clearer quality standards and investments in industrial infrastructure have made it easier for founders to plan long-term manufacturing strategies. Rather than chasing subsidies, entrepreneurs are increasingly aligning with structural improvements that support scale and reliability.

Investor sentiment has evolved alongside this policy shift. Private equity firms and long-term institutional investors are showing renewed interest in industrial and manufacturing businesses, particularly those with strong operating discipline. For founders, this has changed the fundraising conversation. Manufacturing is no longer seen as an unfundable or unfashionable sector, provided the business demonstrates technical depth and execution capability.

Perhaps the most significant change, however, is cultural. A new generation of Indian founders is emerging with hands-on operational experience and a willingness to engage with complexity. Many have worked in global manufacturing environments or studied engineering disciplines that emphasise systems thinking. They view factories not as liabilities but as assets that anchor innovation.

These founders are also redefining what success looks like. Instead of chasing rapid user growth or short-term valuations, they are building for durability. Manufacturing businesses reward patience, process excellence and long-term customer relationships. In 2026, these attributes are increasingly aligned with the global demand for dependable partners in an uncertain world.

The implications extend beyond individual companies. As more founders commit to credible manufacturing, they contribute to a broader ecosystem of skilled workers, component suppliers and technical expertise. Over time, this deepens India’s industrial base and reduces its dependence on imports for critical technologies. It also positions the country to capture greater value in global supply chains, rather than remaining at the margins.

India’s manufacturing story in 2026 is therefore not about volume alone. It is about trust, capability and ambition. Founders doubling down on credible manufacturing are making a statement that India can compete not just on price, but on performance. In doing so, they are reshaping how the world views Indian industry and redefining what it means to build a truly global company from India.

For these entrepreneurs, the factory floor has become more than a place of production. It is where credibility is earned, resilience is built and the next phase of India’s economic ascent is quietly taking shape.

Add businessmax.in as preferred source on google – Click Here

Last Updated on: Wednesday, January 28, 2026 6:02 pm by Business Max Team | Published by: Business Max Team on Wednesday, January 28, 2026 6:02 pm | News Categories: Startup, Trending